Brace is students’ senior design capstone project

Braces for people with scoliosis can be awkward, cumbersome and even painful. A good fit is crucial, especially since the brace is often worn day and night.

Mechanical engineering students at the University of Rhode Island are collaborating with a local doctor and a Rhode Island company to create a brace that, well, fits like a glove—and is just as comfortable.

Gabriella Devine of East Greenwich, Thomas Brey of Manorville, N.Y., Dan Cross of Northborough, Mass., and Christopher Viveiros of Attleboro, Mass., are working on the project with a doctor from Rhode Island Hospital and SIMULIA, the Rhode Island branch of an international computer software company called Dassault Systèmes.

The students are creating the brace for their senior design capstone class in mechanical engineering, which requires students to solve real-world problems with viable products. The students expect to have a prototype in April, after months of research.

“This project will have an impact on patients’ lives so it’s very rewarding for all of us,’’ says Devine. “It’s exciting to combine engineering skills and new technology.’’

The project involves three fields: mechanical engineering; computer simulation; and medicine. To be competitive in today’s workforce, the students say it is crucial to get hands-on experience in fields outside their concentration and keep pace with cutting-edge technology.

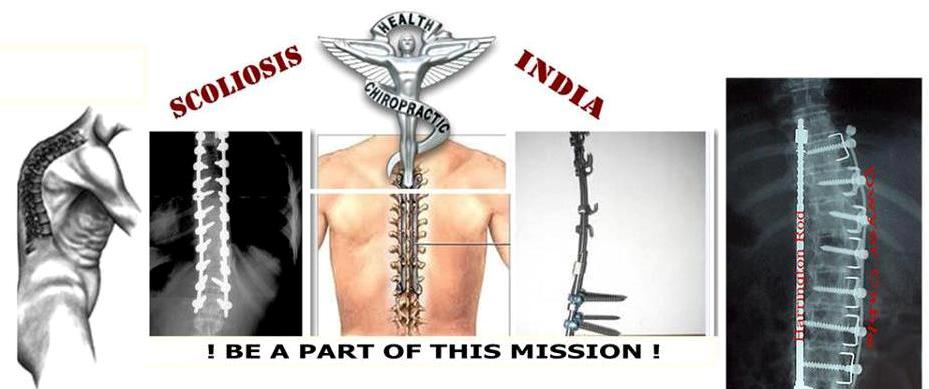

Scoliosis is a curvature of the spine that usually occurs during puberty. There is no cure; however, it is treatable with a brace and, in extreme cases, surgery. Without treatment, the condition worsens and can be disabling.

There are two commonly used scoliosis braces: the Boston brace and the Providence brace, both of which could be improved, say the students.

The Boston brace, also called the underarm brace, is usually prescribed for curves in the lumbar or thoraco-lumbar part of the spine. It is typically worn most of the day under clothing and removed for gym class or sports. The Providence brace, also called a nighttime brace, is worn while sleeping.

“Because they’re bulky, sweaty and restrictive, kids—young girls especially—don’t want to wear them,’’ says Viveiros. “They feel self-conscious in public. We’re trying to make something a little more discreet—and breathable.’’

Now, most doctors use padding to customize a standard brace for each patient. That technique has flaws, say the students. The process is time consuming for the patient and requires many medical visits to make sure the brace is fitting properly.

“This can be an inconvenience for teenagers,’’ says Viveiros. “And the brace itself can prevent kids from participating in activities that their classmates are doing.’’

The URI students’ project involves the latest technology. The students will use a 3D scanner to get the patient’s precise body shape—“and that, we hope, will result in a brace that is completely personalized and form-fitting, yet still effective,’’ says Viveiros. Patients will also be required to get X-rays to determine the extent of the curve.

The students will use a 3D printer to make the brace, and the prototype will be made with plastic. “The plastic could come in different colors, so patients can chose their own color—sort of like braces for teeth,’’ says Viveiros. “We’re adding a little bit of fun to an otherwise difficult situation.’’

In addition to SIMULIA, the students are also receiving guidance from Dr. Craig Eberson, chief of the division of pediatric orthopedics at Hasbro Children’s Hospital in Providence. They met with him not long ago to learn how scoliosis braces are fitted and what can be done to improve them.

At SIMULIA, the students are learning how to use engineering design software that makes the brace as effective as possible with the least amount of material. The new brace will have a lattice-like structure instead of a solid-shell, which requires more material.

“The software is smarter than a human,’’ says Cross. “It’s doing thousands of calculations in an instant, recognizing where the pressure needs to be on the brace to correct the curvature. This is the wave of the future in medical care—using software to solve health problems.’’

The new brace could also be less expensive. Brey says that 3D printing is cheaper because less material and labor are involved. “Right now, 3D printing is pretty much used just to make prototypes. We’re trying to bring 3D printing into the mainstream to produce an actual product that meets industry standards.’’

The students say they are thrilled to be working on a project that will improve lives.

“Our professors are devoted to us and want us to succeed,’’ says Viveiros. “This project is a great start to our professional careers.’’

“Everything we’ve learned in the College of Engineering is being put to use,’’ says Brey. “The college is preparing us for an actual job. When we graduate we can be helpful to a company—and society.’’

On Nov. 8, voters in Rhode Island will be asked to approve Question 4 on the ballot. If passed, the investment will pave the way to attract businesses and create the high-paying, high-skilled jobs Rhode Island needs by authorizing $45.5 million in bonds to expand URI’s highly successful College of Engineering ($25.5 million) and create a URI-affiliated innovation campus program ($20 million) that will pair cutting edge research with private sector investments to create the jobs of the future.

Source : URI , 2nd Nov 2016